Selection of Caliber of Transducer

Selecting same caliber of transducer as the caliber of connected process pipe

It is easy installation for selecting same caliber and the sharp pipe is not needed, But, the flow velocity of pipe must be in the rang of 0.3m/s-12m/s. This selection is useful for the new engineering project normally. When the new engineering project starts, the flow velocity is slower. But it is finished, the flow velocity is in the higher level. It is necessary for this situation to change the full scale flow-rate of flowmeter, and don't replace the flowmeter anymore.

The relationship among the caliber of flowmeter, the flow velocity and flowrate could be seen in curve diagram.( see former page).

Selecting the different caliber of transducer to the caliber of connected process pipe

This selecting is suitable for following circumstances:

A.The flow velocity in pipe is more lower and the flow is more stable. For meeting the requirement to flow velocity range, to select small caliber of transducer against the caliber of process pipe and connect sharp tube with transducer both sides , for increasing flow velocity in transducer.

B.Considering the price of flowmeter , the bigger transducer is ,the more expensive it is. If the flow velocity in pipe is lower and is more stable, we could select smaller caliber of transducer for saving expense of flow-meter and for the better operation of flow-meter.

Some Problems For Adding Sharp Tube

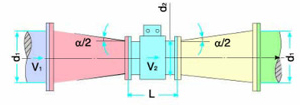

A . Selection of sharp angle of increaser

After having added increaser, and for no-effecting distribution of flow velocity field and accuracy of electromagnetic flowmeter , and regarding the increaser as a part of straight pipe, the center sharp angle of increaser is not larger than 15¡ã. The smaller it is , the better it is.

|

|

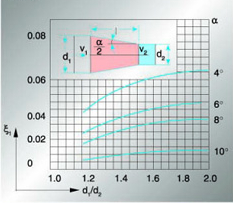

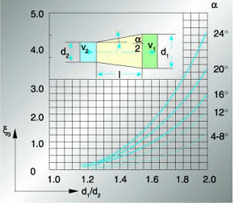

B¡¢ The pressure loss after adding increaser

The total pressure loss is consisted by three pressure loss parts.

The pressure loss in reducing pipe: ¡÷P1=¦Ñ¦Î1V1?

The pressure loss in increasing pipe: ¡÷P3=¦Ñ¦Î3V1?

The pressure loss in measured tube of transducer: ¡÷P2=¦Ñ¦Î2V2?

So, the total pressure loss is: ¡÷P=0.01(¡÷P1+¡÷P2+ ¡÷P3)(mbar)

Where: ¦Ñ is media density(kg/m)? ; ¦Î1 & ¦Î3 are factors concerned with Reynolds number for reducing pipe and increasing pipe respectively ; ¦Î2 is factor concerned with measurement tube of transducer ; V1 & V2 are flow velocities in process pipe and transducer measured tube respectively(m/s).

Reducing pipe Increasing pipe

|

|

About Us Contact Us

©2003-2005 Shanghai Chuangguan instrument & meter CO., LTD webmaster@cgic.biz